The company

Lacroix Emballages, a family firm

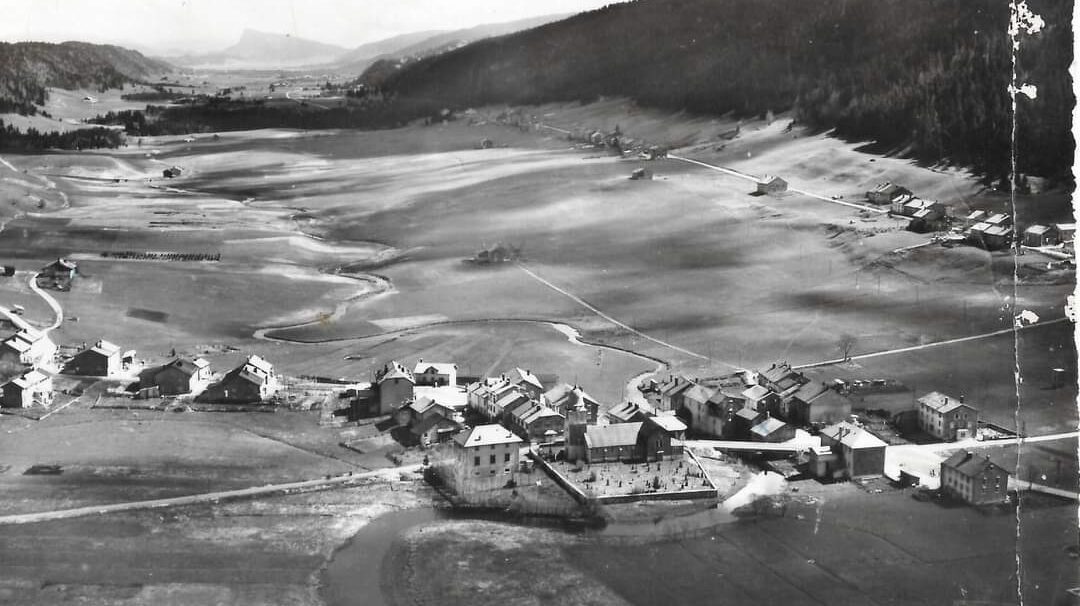

Our family firm was born in 1946, in Bois d’Amont, a small village in the French Jura. A mountain village, where craftsmen worked wood during the long, snowy winters.

The Jura was renowned for the expertise of its boisseliers who crafted wooden boxes and other items, and we started out by making wooden objects, as one of many workshops in the Jura.

Over the years, we began to develop more and more precise techniques for shaping wood, and a bold idea started to form in our head: maybe we could put our know-how to good use with local cheese makers, of whom there were also very many in our region.

And that’s how we decided to develop food packaging, meeting cheese producers’ needs in terms of communication and long-term protection of the products.

Know-how continually developed since 1946

Our strategy today is still, after almost 80 years in business, to pay attention to what our customers want and adapt to changes in their markets. With the development of printing techniques, later we started to design cardboard packaging, a lighter material that allows better quality printing. This enabled us to offer packaging to set our customers’ products off to their best advantage with more sophisticated decorations and a wider range of colours.

We have also developed plastic packaging to keep up with developments on the packaging market and design strong, impermeable packaging allowing the preservation of foods more likely to deteriorate. And so our product ranges have evolved and been perfected thanks to years of experience and research.

Our packaging solutions are no longer just to protect dairy products; now they serve to reheat ready meals, showcase foodstuffs and preserve fresh produce.

But our commitment doesn’t stop there. Sustainably has always been in our group’s bloodstream, as it has always been important for us to reduce our ecological impact and control our energy consumption over the long term.

Eco-design has therefore become an absolute priority, and our research and development departments works hard every day to propose innovative and sustainable products.

Sites close to our customers

With 31 production sites in 10 countries, our development abroad is closely linked to our desire to be close to our customers, to understand their needs and adapt our services accordingly.

To guarantee their satisfaction, we have introduced a full-service offer, which goes beyond simply supplying packaging. We offer customised support at every stage, from the idea for the design through to delivery of the finished packaging.

We are also well aware that every project is unique, with its own challenges and requirements. That’s why we are doing everything we can to offer tailored solutions adapted to every customer’s specific needs.

To provide this service, the group has:

3 product R&D offices

2 veneer peeling and veneering units

4 engineering shops and design offices

6 printing shops (cardboard, IML)

A SPECIFIC NEED ? A REQUEST FOR A QUOTATION ?