From then to now …

The Groupe Lacroix is an innovative company that has always adapted to market trends and customer demand. An independent firm that has successfully taken on board different types of know-how to be more flexible and responsive. A family firm that has always been close to its staff to move forward with them.

Curious to know more? Find out how the company has changed and developed in a few key dates.

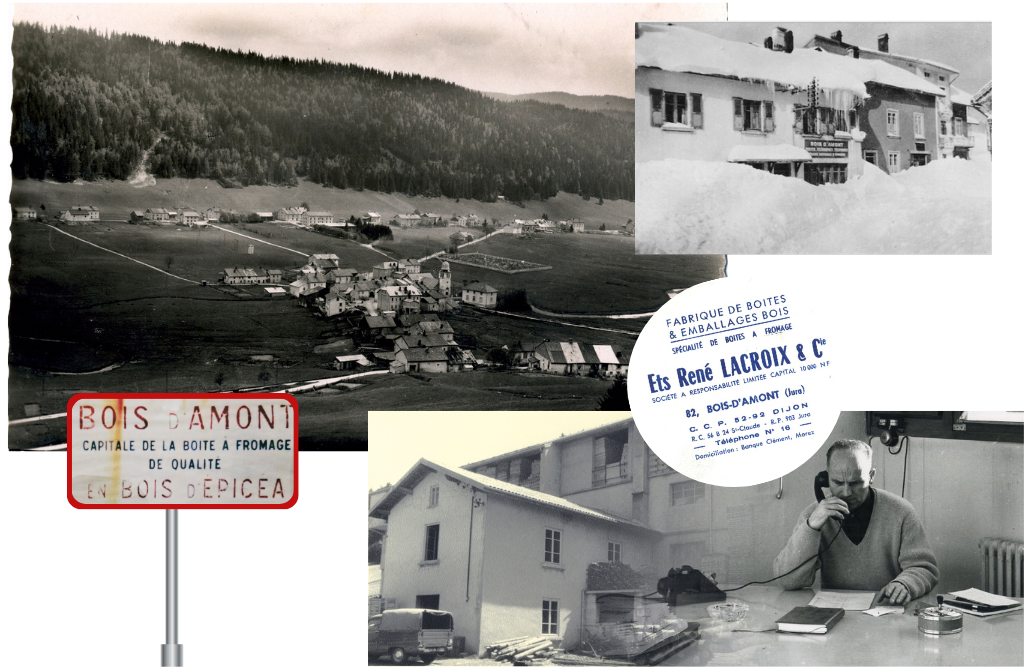

1946, the story begins

WOODEN BOXES IN THE BEGINNING

The company was founded in the Haut Jura region in 1946 by René Lacroix, grandfather of the firm’s current directors. It made wooden implements, toys, boxes and items for schools.

In 1953, under the name “Ets René Lacroix”, the firm began to specialise in making boxes and packaging for cheese. This was a traditional activity that occupied the inhabitants of Bois d’Amont in winter, with the village being known at the time as the “cheese box capital”. There were in fact some thirty firms making and selling boxes of every possible size.

At the time, the cheese was in direct contact with the box. Spruce, a common species in the Jura mountains, offered good protection of the cheese, keeping it fresh without altering its taste or smell. Later on, it would be replaced by poplar wood.

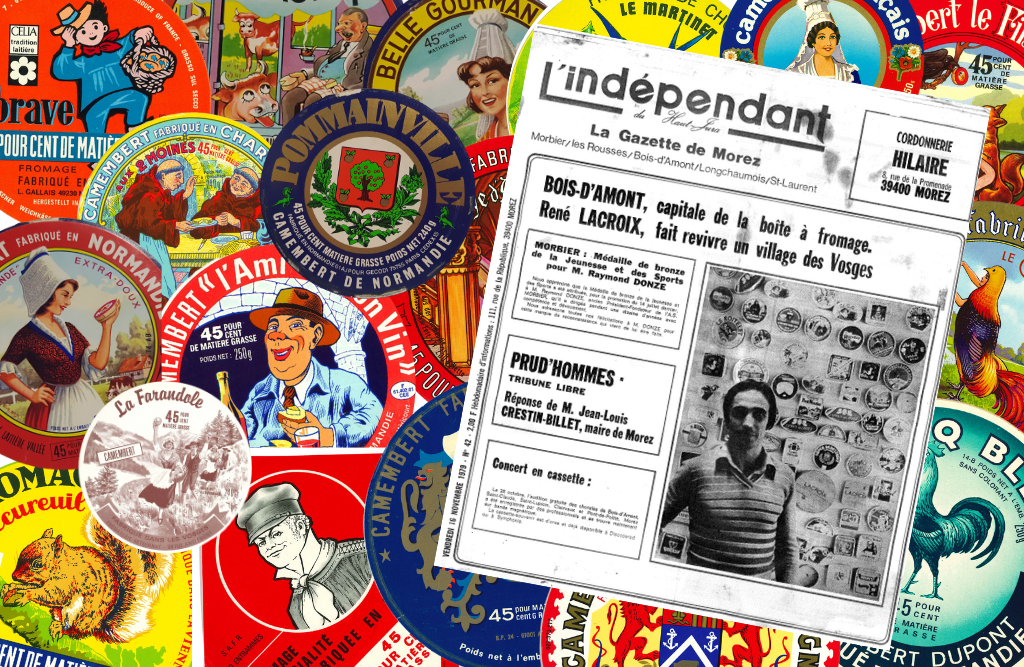

SWEET NOTHINGS

Cheese boxes, a means of communication as good as any other!

The 60s and 70s

CLOSE RELATIONS WITH OUR CUSTOMERS

Stay as close to the customers as possible…. This has been a leitmotiv that has run through the firm’s strategy for decades and still applies today. To get closer to the producers of Munster and Carré de l’Est cheeses, a first factory was opened at Hennezel in the Vosges in 1966. That minimised transport, but also allowed us to be more responsive.

In the 60s and 70s, the company diversified into cardboard cheese packaging. This was more flexible, more economical and more creative, as cardboard allowed cheese producers to feature their brands in glorious colour. This was one of the first major technological changes the company embarked upon.

We opened our first printing works at Sans Vallois in the Vosges in 1976. Our Sagy en Saône et Loire site specialises in the production of the iconic Caprice des Dieux cheese box.

The 80s and 90s

VERTICAL INTEGRATION

Demand and volumes continued to grow. Two new sites opened in Normandy, the emblematic home of Camembert cheese. The group also opened a veneer peeling and manufacturing site to provide quality wood.

Making wooden and cardboard cheese boxes is a very specific activity. It involves mastering a number of different techniques, such as stapling, crimping and press forming. That is why company created its own engineering workshop in the early 80s. It has all the expertise in manufacturing processes and machinery to be able offer differentiating solutions to its customers.

The 80s were also marked by the company’s move into plastic packaging. In response to demand from its customers and to keep up with market trends, this period saw the launch of the first injection-moulded and thermoformed plastic packaging.

The 2000s

THE AMERICAN ADVENTURE

At the end of the 90s, the adventure continued overseas. Our customers were developing their business in America and encouraged us to go with them.

It was through a partnership in Canada that we launched our business in North America. The plastic injection-moulding technique with in-mould labelling (IML), in which our French teams were proficient, was much less common in North America. We quickly saw the openings grow.

Our subsidiary IML Containers expanded and now has 7 production sites, including 2 in South America. And to keep them supplied regularly and quickly, 3 printing works were created under the name IML Labels.

The 2000s

EXPANDING EASTWARDS

In the 2000s, market opportunities started to arise in the Eastern European countries, as they gradually opened up internationally.

For the Lacroix group, things began in Poland, with 2 manufacturing sites. One of, Woodpak, specialises in wooden trays and the other, Lacroix Opakowania, in cardboard packaging. A few years on, a printing shop opened its doors.

Later, a new site was built in Romania, Lacroix Ambalaje, specialising in injection-moulded plastic packaging.

After that came a factory in Turkey and another in Germany to manufacture cardboard boxes and trays. Finally, the Lacroix Group moved into Asia with an injection moulding site near Ho Chi Minh City.

And now?

NEW CHALLENGES

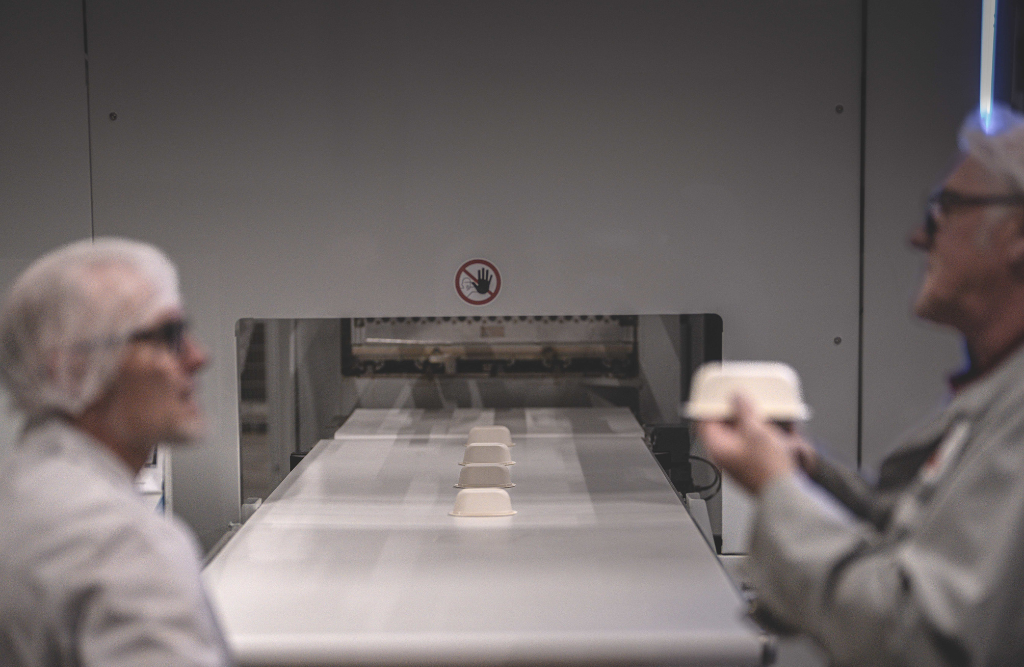

The market and consumer expectations are changing. Designing the best possible packaging which protects what it contains whilst fitting into the circular economy is the goal that our R&D teams are focusing on. In line with this strategy of constantly moving forward and progressing, in 2021 the company took the bold step of introducing a new material made from renewable resources, cellulose.

As well as working on innovations in terms of new packaging solutions, the company has continued its development in close proximity to its customers with a brand new site that opened in 2022 to produce wooden trays.

A SPECIFIC NEED ? A REQUEST FOR A QUOTATION ?